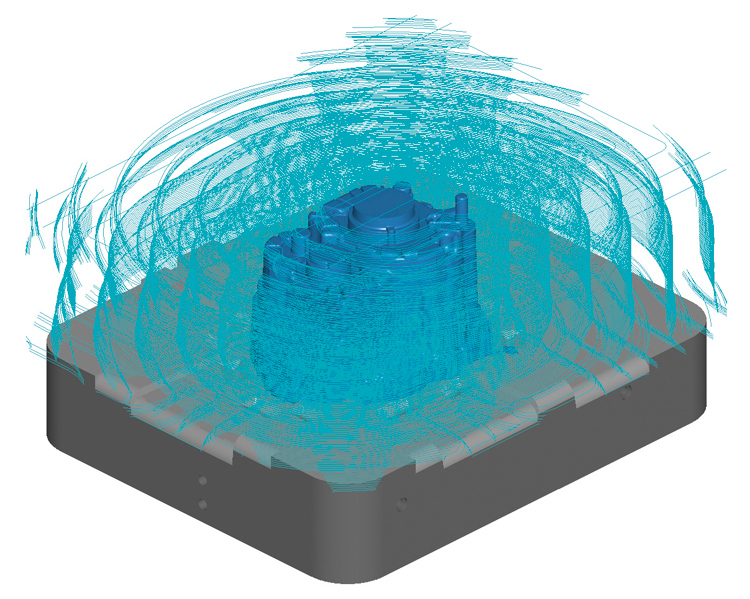

NCG CAM has an additional routine for roughing which is ideal for core forms, where the machinist wants to rough away the material by machining from the outside, whilst maintaining climb milling. All toolpaths start in fresh-air at the given Z-depth, and work into the middle.

NCG CAM creates a safe boundary from the outside form of the core. All toolpaths then start from this safe boundary, approach the material with a lead on arc, machine with no more than half the diameter of the cutter, then lead off with an arc away from the material back into the safe zone.