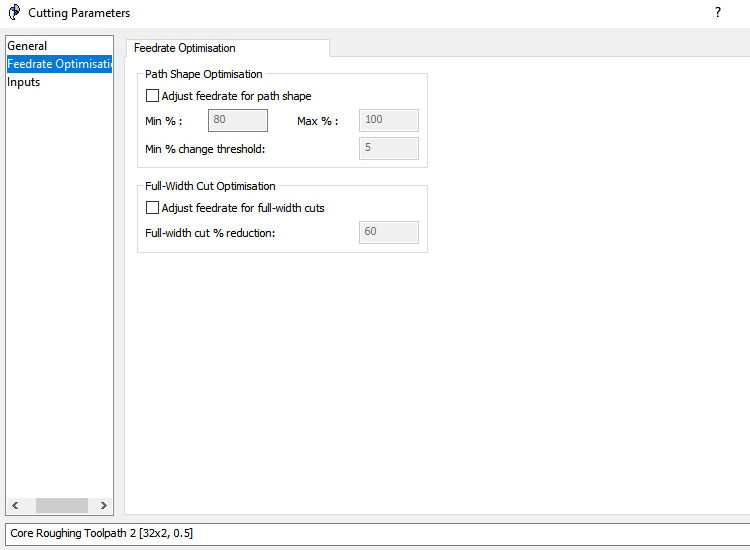

NCG CAM has feed-rate optimisation for area-clearance, core roughing, rest roughing and water-line machining.

The software is aware of the cutting conditions, if the current toolpath is machining an external corner, then the feed-rate specified can be maintained. In areas such as internal corners where the cutter will be in full contact, NCG CAM looks ahead and adjusts the feed-rate down to maintain accuracy and prolong tool-life.

When NCG CAM is performing a ramping entry move for area clearance roughing, the ramping feedrate is used. Once the cutter is to depth, the cutting feed-rate can also be reduced as this first cut will be the full width of the cutter. This is then returned to the normal feed-rate once the cutter is not making a full width cut.