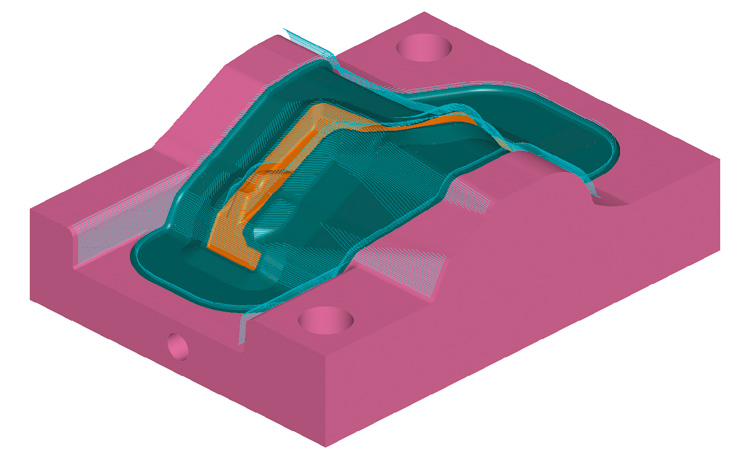

Waterline passes can be used for semi-finish and finish machining the more vertical areas of a part.

If a slope angle is specified, for example between 30° – 90°, the steeper areas are machined, leaving the shallower areas between 0° – 30° for more appropriate strategies. These passes can be constrained to a boundary or by the selected surfaces. Waterline machining also has the feed-rate optimisation option.

Linking options for waterline passes include bi-directional and one-way machining. Bi-directional machining will maintain contact with the part by climb milling one-way, then conventional milling the other, but should only be used for non-critical machining. One-way machining is the default and ensures a climb milling cutting action, maintaining tool-life accuracy and good surface finish. The linking move may be on the surface, or can be forced off the surface with user defined angle of lead in / out and lead extension to help with cutting some specialist alloy materials. It is also possible to set conventional milling if required.