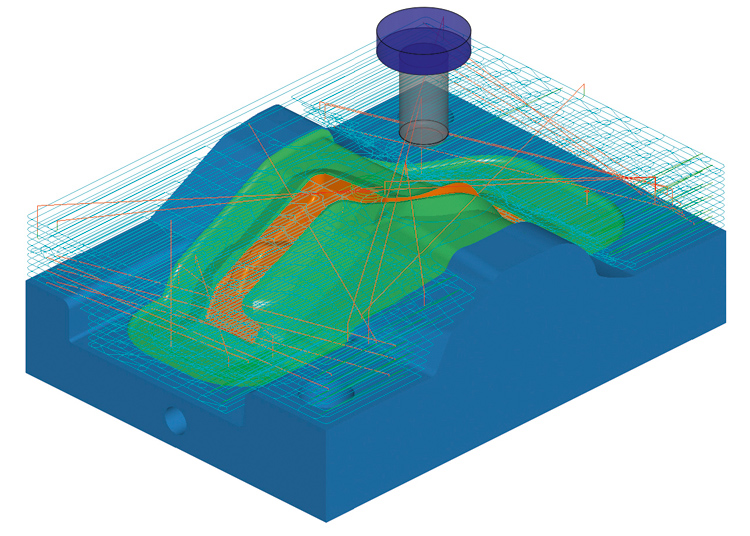

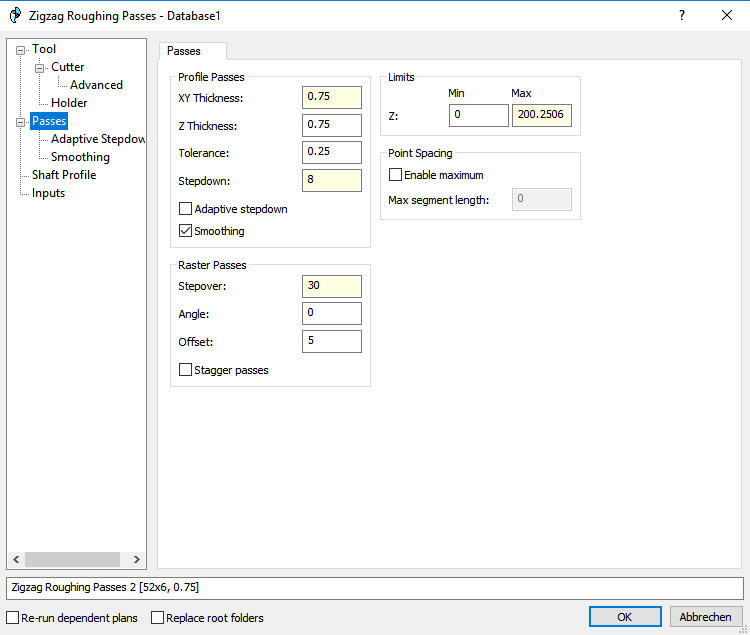

Zig-zag roughing in NCG CAM will take linear cuts across the job at fixed Z levels, similar to area clearance or core roughing passes. As these passes are linear, there is far less data involved and fewer changes of machine directions. At each level a profile pass is performed to remove the cusps around the parts profile at that level, before moving down to the next Z-level.

When creating the passes it is possible to stagger the passes. This is of benefit if roughing with a ball-nose cutter as the cusp height on the bottom of the cutter is kept to a minimum. When linking zig-zag roughing passes, there are options for one-way, bi-directional and zig-zag for the stock removal passes and climb or conventional for the profile pass.

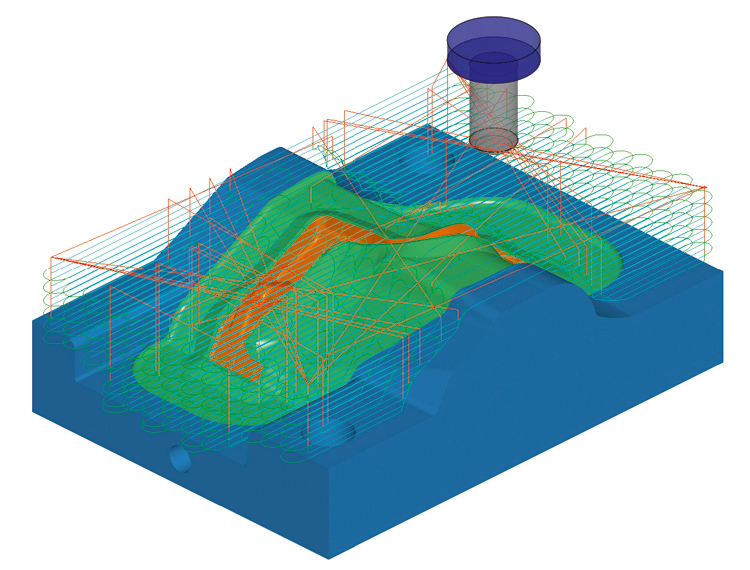

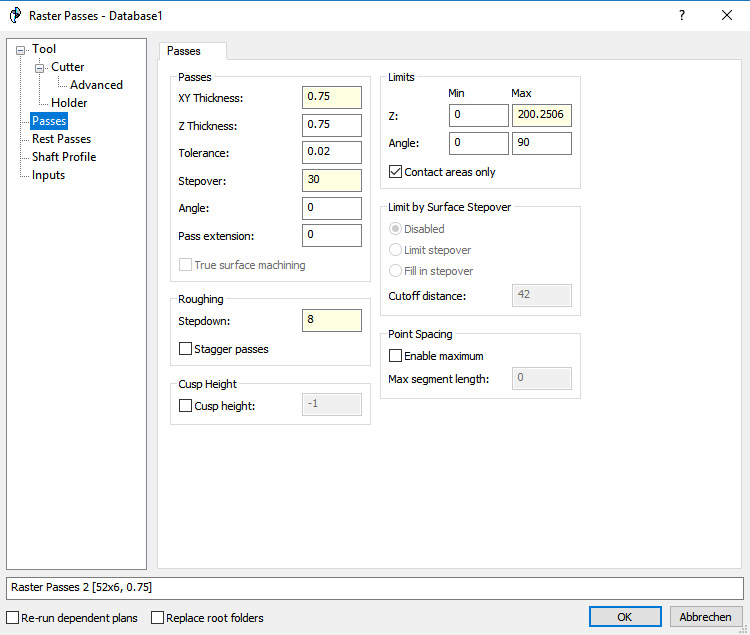

NCG CAM has a raster roughing routine that will allow the roughing out of a part with a raster strategy that is also broken into Z-bands. When the cutter comes up against the form it follows the form up to the top of the Z-band for those passes; this ensures there is not a big step left. If using a ball-nose cutter the passes can be staggered to leave the minimum cusp height from the bottom of the cutter.

The linking for raster roughing passes has options for one-way and bi-directional.